At Dash Dynamics, we have developed our own unique, and innovative way of positioning letters correctly on number plates using a number plate jig.

In order to be compliant with Section II of the Road Vehicles (Display of Registration Marks) Regulations 2001, there are very specific measurements that a license plate needs to adhere to in order to be road legal. Therefore, we have designed a special number plate jig specifically for the purpose of correctly placing the lettering on number plates in accordance with these requirements.

We recently released a video showing exactly how our special manufacturing jig works, which you can watch here:

Number Plate Jig Introduction

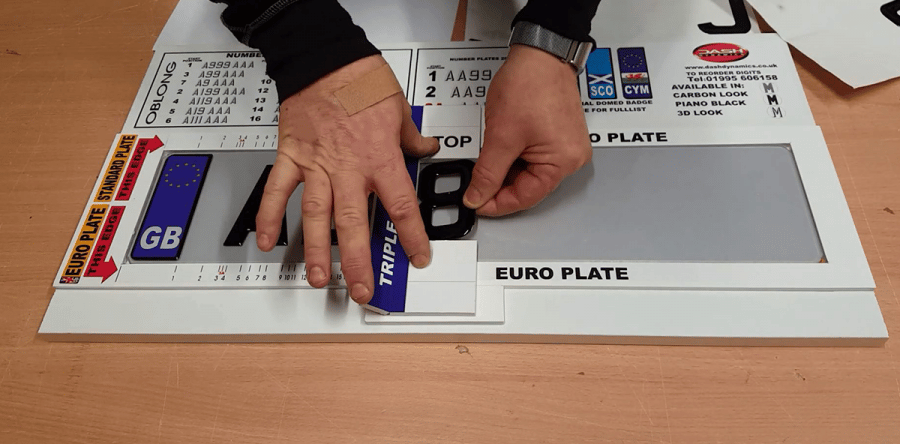

As you can see in the video, our jig has specific markings to allow for accurate placement of letters. The number plate slots into the base plate and the markings on the jig run along the top and bottom. It works a bit like a simplified slide rule. The two separate markings are for both a Euro plate section, and non-Euro plate section. So, the jig can be used for plates with or without a Euro badge.

The jig has numbers running along it that indicate the start of the first letter. It includes everything from the very first plate ever made, A1, through to the very latest plates. So when you look at the number plate you’re creating you choose the start number from the table at the top. You select the number by matching the letter/number combination with the same style as shown. The video above will assist you in this aspect and is well worth a watch.

The key component of the jig is the cursor, which has a flap over section. Both sides of this flap have been very specifically measured to the legal requirements needed for letter placement. The cursor slides easily onto the base plate and can be lined up with numbers shown on the jig. Using the single space measurement of 11mm, the cursor measures exactly where the left-hand side of the cursor needs to be positioned prior to placing the first letter within the cut out in the cursor. The letter is placed right up against the side of the cut out. This ensures it is placed with the correct amount of space from the start of the plate.

When the first letter has been placed, the left-hand edge of the 11mm spacer on the cursor is moved along to sit right up against the letter and the second letter is placed accurately within the cut out. This is repeated until the entire first section of the plate is completed.

The distance needed between the age identifier and the random letters on a number plate is 33mm. So, in this instance you use the 33mm flap on the cursor, the triple space section, and then place the letter. This creates an exact 33mm gap.

You then carry on with the 11mm single space to complete the rest of the letters.

Once you’ve placed all of the letters, you will have a completed plate that has the exact measurements needed to ensure that the plate is road legal. By pressing on the edge of the jig, the plate easily pops out of the base plate, and it’s all ready to ship out to your customer.

Dash Dynamics Number Plates

The Dash Dynamics number plate manufacturing system can only be supplied to DVLA Registered Number Plate Dealers, along with our high-quality black 3D and 4D resin domed number plate letters.

Our letters don’t interfere with the legibility of the registration marks and contain no reflective properties, so they won’t raise any issues with the authorities.

The 3D and 4D letters we supply are exactly cut to the same shape. This allows you, the dealer, to combine both products together to create a plate with the Resin Domed 3D letter fitted to the top of the 4D letter to make a truly bespoke product should the customer wish to take this additional option.

Unlike other manufacturers of 4D letters, we subtly radius the inside and outside corners so there is a much reduced risk of the end user injuring themselves on sharp corners. Our 4D letters also come with high quality 3M adhesive already applied to the rear, ensuring the very best in adhesion. No more messing around with acetone, risking damaging the plate through dripping the acetone on it whilst applying the letters. No more fiddling around with Superglue where the bond between the plate and letter will eventually break down due to atmospheric conditions and water, thus causing the letter to fall off.

Coupled with our bespoke jig to help ensure the correct spacing of the letters, when you get your number plate supplies from Dash Dynamics, you’re guaranteed a road legal solution to 3D number plates.